RENNtech 550 Sport Package

Product Information

RENNtech has developed this power packed yet stylistically subtle package specifically for the S550 sedan. RENNtech achieved this with just a few modifications that make a vast improvement in the overall presence and performance of the S-Class in stock trim.

The tasteful exterior upgrades start off in the rear with a pre-preg carbon fiber rear decklid spoiler, designed in-house at RENNtech and manufactured in the USA. Stainless Steel Sport Mufflers make sure that the S 550 turns heads before you can even see it.

Electronic actuated valves eliminate unwanted loud exhaust noise while driving in low RPM ranges. RENNtech valved sport muffler utilize the electronic OEM actuators. All exhaust systems are designed and manufactured at the RENNtech HQ in Stuart, FL.

Optional RENNtech Deep Monolite Wheels are available in a 10-, 10.2- and 16-spoke design with a 21" front and 22" rear fitment. You can choose between three different finishes: Brushed Aluminum, Gunmetal or Titanium.

The RENNtech S550 tune unleashes the true potential of the 4.7L V8 Biturbo with power figures boosted up to 540 horsepower and 705lb-ft of torque. Throttle response is also greatly improved, transforming the standard S 550 sedan into the quintessential perfect blend of stately executive class and AMG-esque performance. With a minimalistic yet effective approach, RENNtech has proven there is a void to be filled between the S550 and S63 variants.

RENNtech 550 Sport Package includes:

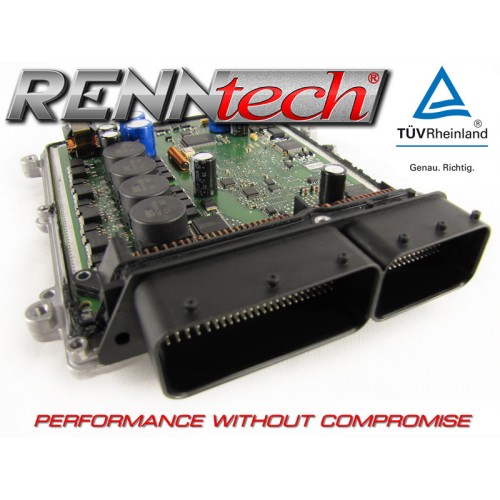

- RENNtech ECU Upgrade

- RENNtech Carbon Fiber Decklid Spoiler

- RENNtech Stainless Steel Sport Mufflers w/Electronic Actuated Valve System

- Optional: RENNtech Deep Monolite Wheels ($9,880)

W222 - S 550 – M278 | 4.7L V8 BiTurbo Stock Performance:

- Rated by Mercedes-Benz: 449 HP @ 5,250-5,550 RPM | 516 LB-FT @ 1,800-3,500 RPM

- Rated by RENNtech: 474 HP @ 5,050 RPM | 566 LB-FT @ 2,350-3,650 RPM

W222 - S 550 – M278 | 4.7L V8 BiTurbo RENNtech Upgraded Performance:

*Applies to all Models, crank power calculation based on 17% Drivetrain loss on 4-MATIC models

- Rated by RENNtech: 540 HP @ 5,300 RPM | 705 LB-FT @ 3,400-4,200 RPM

448 awhp @ 5,300 RPM | 585 awtq @ 3,400-4,200 RPM

RENNtech Deep Monolite Series Features:

- Set of 2 Front and 2 Rear Wheels

- Signature RENNtech 10, 10.2 or 16 spoke design, Designed and developed specifically for the Mercedes-Benz S-Class

- Lathe Grooved backpad process for weight reduction Exclusive

- CNC machined RENNtech center cap design “RENNtech” logo and “Forged” machined in adjacent spoke windows

- Engineered to utilize OEM lug bolts for most applications

- Titanium lug bolts are an optional upgrade for this wheel

Wheel Specifications:

| Front: | |

| Style: | Deep Monolite 10, 10.2 or 16 |

| Finish: | Brushed Aluminum, Gunmetal or Titanium |

| Size: | 21" x 9.0" ET 36 |

| Construction: | 1 pc. Forged Monoblock |

| Tire Size: | 245/35/21 |

| Rear: | |

| Style: | Deep Monolite 10, 10.2 or 16 |

| Finish: | Brushed Aluminum, Gunmetal or Titanium |

| Size: | 22" x 10.5" ET 40 |

| Construction: | 1 pc. Forged Monoblock |

| Tire Size: | 295/25/22 |

What exactly is prepreg carbon fiber?

- Prepreg is widely known as the finest process in carbon fiber manufacturing and has been used for aerospace and military applications because of its superior consistency in weight, thickness, fitment, resin, carbon layout, and overall quality.

- The pre-impregnated (prepreg) fiber method creates stiffer, stronger laminates with controllable, predictable results and the result is a consistent, tight fiber weave which not only looks amazing, but adds strength. Other companies use a lower cost, wet-layup method which results in components of inferior, strength, appearance and overall quality.

- To explain this process in short, the fiber is pre-impregnated (hence the name) with resin at a production facility, rolled on spools, and frozen to prevent the resin from curing prematurely. This material is than cut and hand laid into a mold to the proper thickness and cured at strictly controlled temperatures. This process creates a laminate with a precisely controlled resin volume and in turn is 20-30% stiffer and stronger than an equivalent thickness wet laminate process.

- This ensures our customers receive components which not only look good on the vehicle standing still, but won’t crack, warp, fall off or fade when mounted to the exterior of their vehicle after six months or while driving at high speed.